Critical Speed Of Ball Mill | Crusher Mills, Cone Crusher ...

critical speed of a ball mill and ball size – Grinding Mill . Posted at: July 30, 2012. Ball mill – Wikipedia, the free encyclopedia The critical speed can be understood as that speed .

WhatsApp)

WhatsApp)

critical speed of a ball mill and ball size – Grinding Mill . Posted at: July 30, 2012. Ball mill – Wikipedia, the free encyclopedia The critical speed can be understood as that speed .

Fig. 10, Fig. 11 results obtained by us on variation of S ** with ball load for 70% and 55% critical mill speed. It can be seen that at 70% critical speed the maximum S ** value is observed at a J value of about, while at 55% critical speed the maximum value is observed at a J value of about

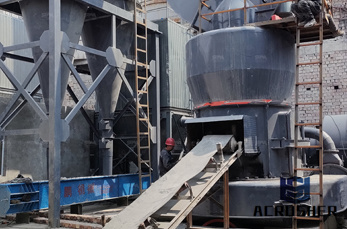

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Calculator For Ball Mill Critical Speed Critical speed calculation of ball mill critical speed .:. Mill Critical Speed Determination The "Critical Speed" for a grinding mill is defined as the rotational speed where You may use the Mill Liner Read more

critical speed of ball mill. ball mill critical speed, ball mill efficiency,ball mill media. as a professional intermittence ball mill product, drum dryer manufacturer, bailing machinery analyzes the factors affecting the production efficiency, looking to produce help and support to customers. with respect of rotating speed.

Jan 13, 2013· Ball Mill Critical Speed – #2fishygirl on Scribd | Scribd. The analysis of size reduction in tumbling ball mills using the concepts . which are ground at the condition 70% of critical speed of cement ball mill in . »More detailed

ball mill critical speed calculation CGM Grinding Plant. Search Results Search Results for "ball mill critical speed calculation" Mill Critical Speed Determination ... defining some critical .

In solid mechanics, in the field of rotordynamics, the critical speed is the theoretical angular velocity that excites the natural frequency of a rotating object, such as a shaft, propeller, leadscrew, or the speed of rotation approaches the object''s natural frequency, the object begins to resonate, which dramatically increases system vibration.

Jan 22, 2013· > Mining News > why critcal speed is necessary in bowl mill; Print. why critcal speed is necessary in bowl mill. Posted at:January 22, 2013[ ... PERFORMANCE ANALYSIS OF COAL MILLS – Docstoc ... »More detailed. how to calculate critical speed of ball mill – Grinding Mill China » used blue bowl gold . You want to know why critical speed ...

Mill Critical Speed Determination. ... This formula calculates the critical speed of any ball mill. More details » Get Price. Ball Mill Critical Speed · Mineral Processing/Metallurgy Research ... Jan 22, 2016 ... Use our online formula. Ball Mill Critical Speed. The mill speed is typically defined as the percent of the Theoretical Critical ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical ...

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed. The faster the mill speed, the greater the wear on the rods and liners.

The critical speed of a SAG mill is the speed in RPM''s at which centrifugal force causes the material being ground to be held against the inside of the shell. ... When setting up a ball mill, it ...

Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Excel speed/feed calculators for Ball Nose Finishers, . 90° Square Shoulder Mills; Ball Nose . and the calculator will automatically provide the necessary speed . Mill Critical Speed Determination –

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Critical Speed Of Ball Mill | Crusher Mills, Cone . critical speed of a ball mill and ball size – Grinding Mill . Posted at: July 30, 2012. Ball mill – Wikipedia, the free encyclopedia The critical speed can be ... » More; critical speed of ball mill formula in South Africa . Critical Speed Of Ball Mill Calculation India.

How can I determine the best RPM for Dry Ball Milling machine in order to let the balls to fall from the best angle(s) ? ... 65 and 85 % of the critical speed of the mill. ... of your ball mill ...

how to calculate ball mill rotational speed. How to calculate ball mill rotational speed . critical speed of ball mill . derivation for the critical speed of ball mill Ball mill critical speed, how to calculate the ball mill speed iron ore 562018 The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal how to calculate the ball mill speed.

critical rpm of ball . why mills are driven below critical speed . ball mills rpm notes Mill Critical Speed Determination. This is the rotational speed where balls will not fall away from. Contact Supplier

Figures for the popular mill types. 3 c is the mill speed measured as a fraction of the critical speed. More reliable models for the prediction of the power drawn by ball, semiautogenous and fully autogenous mills have been developed by Morrell and by Austin. (Morrell, S. Power draw of wet tumbling mills .

In general, it is necessary to calculate the critical speed of a rotating shaft, such as . .:. Mill Critical Speed Determination. Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell''s inside surface.

what is critical speed in a ball mill Ball Mill Operating Speed Mechanical Operations, The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm ... why critical speed of ball mill is less than one .

WhatsApp)

WhatsApp)