What''s the Difference Between SAG Mill and Ball Mill ...

Nov 26, 2019· Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc. Grind and blend solid or hard materials into smaller pieces by means of .

WhatsApp)

WhatsApp)

Nov 26, 2019· Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc. Grind and blend solid or hard materials into smaller pieces by means of .

LG A mill power equation for SAG mills. Minerals and Metallurgical Processing. Feb 1990 pp5762. Gross power No load power Net power drawn by the charge () The net power is calculated from Net power e! c./ Watts () In equation, D is the diameter inside the mill liners and Le is the effective length of the mill including the ...

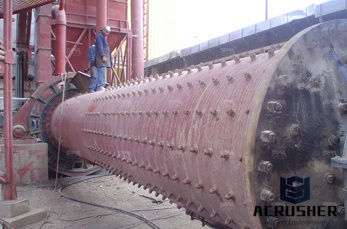

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

SAG is an acronym for SemiAutogenous Grinding SAG mills are autogenous mills but use grinding balls like a ball mill A SAG mill is usually a primary or first stage dry ball mill principles pdf Ball mill grinding machine operation working principle parameter 17 More Info sag and ball mills principles pdf pravpohybueu. sag and ball mills ...

Mar 13, 2015· Ball mill / sag mill shell Change Time laps film Duration: ... Ball mill manufacturing for BHAGWATI FABRICATORS BEAWAR RAJSTHAN AND Duration: 1:14.

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Ball mill preventive maintenance, SAG mill, AG mill . Aug 11, 2015 · Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills.

Advanced Controller for Grinding Mills: Results from a Ball Mill Circuit in a Copper Concentrator ... throughputlimited ball mills and Semiautogenous grinding (SAG) mills. Given this large operational ... to the ball mill and the outflow from the ball mill goes to a sump where additional water is added. The

ball mill can be reorganised as [7] and [8], where B''Wio and A''Wio are the corrected operating work indices and WAG/SAG, WBM are the respective power draw of AG/SAG and ball mills. Note that the ball mill operating work index is applied only on the portion that needs the additional grinding (Q2), which renders to the AG/SAG mill the

singlestage SAG mills to the largest mill in the world – with a 40foot diameter and 28 MW of motor power. Ball mills Ball milling is the most common application for horizontal tumbling mills. Outotec offers a full range of ball mills to suit a wide variety of duties, from a few hundred kW all the way up to 20 MW and beyond. Rod mills

We offer autogenous (AG), semiautogenous (SAG), ball, rod, and pebble mills in sizes ranging from kWs up to 30+ MW. Our product range also includes a number of unique solutions, including the world''s largest acidresistant grinding mills, which can operate with extremely corrosive slurry.

Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and .

Following the SAG mill will be two 9,000hp ball mills, each one 20ft in diam. and 331/2ft long, that do the finish grinding. Built by the Allis Mineral Systems Grinding Div. of Svedala ...

1 IMPROVEMENTS IN SAG MILL THROUGHPUT FROM FINER FEED SIZE AT THE NEWMONT AFO OPERATION *Adrian Dance1, Sonny Mwansa2, Walter Valery 2, George Amonoo3 and Bryon Bisiaux3 1SRK Consulting (Canada) Inc 22nd Floor, 1066 West .

offers AG mills, SAG mills, ball and pebble mills, and stirred mills to your needs. By continuing to use the site, you agree to the use of cookies. You can find out more by reading our cookie policy. By continuing to use the site, you agree to the use of cookies. You can find out more by .

As well as ever larger SAG mills, ball mills are also expanding in size. In the late 1990s the trend moved towards using GMDs to power these larger ball mills, as well as using the drive to vary the speed. GMDs quickly moved from 20'' ball mills, expanding to 24, 25 and then 26'' mills. In early 2010 ABB commissioned the first GMDs for two 27 ...

mill. As such, primary ball mills should be designed with the rod mill work index, and singlestage ball mills should be with both the rod mill and ball mill indices. This is because it is common to observe a difference (sometimes significant) between the rod mill and ball mill index values for a given ore type (McKen, Verret, Williams, 2006). On

THE EYES HAVE IT: IMPROVING MILL AVAILABILITY THROUGH VISUAL TECHNOLOGY ABSTRACT This paper describes the introduction of two unique tools that discard the longstanding notion that it is impossible to assess liner condition without stopping the mill .

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today''s global markets, expanding mining groups are trying

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in diameter, powered by a 28 MW (38,000 HP) motor.

This is why SAG mills are usual fitted with Squirrel Cage Induction Motors (SCIM) and Frequency Converters (VSD''s). NB: Although this is also gaining acceptance on large Ball Mills. This allows the operator to "tune" the mill to the ore and liner characteristics.

semiautogenous (SAG) mill and two ball mills, each with 13 megawatts (MW) of installed power, was expected to be SAG mill limited when treating competent basement rock. Ausenco Services Pty Ltd (Ausenco), was engaged to help optimise and enhance the productivity of the Phu Kham comminution circuit over an eightmonth period.

The designs of autogenous and semiautogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

LARGE DIAMETER SAG MILLS NEED LARGE DIAMETER BALL MILLS – WHAT ARE THE ISSUES? ... (PDF Available) ... From the literature it is apparent that in .

WhatsApp)

WhatsApp)