Minnesota Iron Mining Process YouTube

Jun 06, 2016· Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

WhatsApp)

WhatsApp)

Jun 06, 2016· Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is ...

The process of extracting iron from ore produces great quantities of poisonous and corrosive gases. In practice, these gases are scrubbed and recycled. Inevitably, however, some small amounts of toxic gases escape to the atmosphere. A byproduct of iron .

Nov 21, 2014· The iron ore that is blasted is stacked and loaded upon large dumpers to be moved to the blast furnaces for smelting process. Benches are made for the process of iron ore mining. Mechanized mining involves creation of benches that are used for the purpose of drilling, blasting, and finally the transportation of the iron .

Iron Ore Smelting Process Brighthub Engineering. The Mining of Iron Ore Iron ore mining was a thriving industry in many parts of the world with the smelters being located as close to the mines as possible However as larger mines where more efficient mining of higher iron .

Iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted. Iron ore mining is classified into two categories manual mining and mechanized mining methods. Haematite and magnetite are the most commonly found iron ore minerals. Deposits of iron ore such as haematite containing iron oxide are found in sedimentary rocks from which the oxygen is removed from the ...

The Process Of Mining Iron; Iron processing Britannica Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation Iron processing, use of a smelting process .

Everyday, in nearly every facet of life, we use products created by Minnesota''s iron mining industry. Unearthed on northeastern Minnesota''s Iron Range in 1884, iron mining has longplayed, and .

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation''s steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces.

Mar 14, 2014· The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and ...

The process of mining low grade iron ore, or taconite, requires massive resources. Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required. The equipment used includes diamond bit rotary drills, hydraulic shovels

Mining of Iron Ores IspatGuru. Hematite, Iron ore, mines, mining, Mining of Iron Ores. The total movement of ore and waste constitutes the mining process. Often more waste than ore is mined during the life of a mine, depending on the nature and location of the ore deposit. Removal and placement of overburden is a major cost in the mining .

Iron Mining Process Minnesota Iron. Iron Mining Process. From blasting to crushing to separation more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our .

Mining iron ore begins at ground level. Taconite is identified by diamond drilling core samples on a grid hundreds of feet into the earth. Taconite rock comprises about 28 percent iron; the rest is sand or .

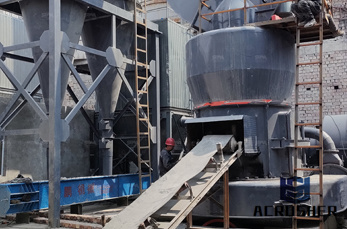

Processes In Iron Mining fraessle . Processes In Iron Mining. Production Process of Iron Ore Generally the processing of iron ore needs several processing stages including crushing grinding ore beneficiation concentrating drying etc The equipments for iron .

Iron ore mining process Crushing equipment: crusher(30mm):Jaw crusher crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Magnetic .

World resources are estimated to be greater than 800 billion tons of crude ore containing more than 230 billion tons of iron. The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process. Sinter is the primary feed material for making iron .

Iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth''s crust, and it is the ...

3. Rio Tinto. Rio Tinto is a diversified mining company. It''s a leading producer of the three most consumed industrial metals iron ore, aluminum, and copper as well as a variety of other ...

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill, Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer.

Stone Crusher Mining Iron Ore China. Stone Crusher Mining Iron Ore China. . With more than 2500 case sites the scientific management method the refined manufacturing process and the innovative manufacturing concepthave rapidly grown into the mining .

To efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory. Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron .

Apr 09, 2015· Exploitation of existing iron ore deposit is the easier part of the mining operations. The harder part is to find new ore deposits and to define their extent and the iron content (grade). Exploration is the process by which the accumulations of iron .

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed ironbearing minerals are oxides, and iron .

WhatsApp)

WhatsApp)