Calcined Kaolin

Of course, mixing the raw and calcined materials must take into account the LOI of the raw material (12% less calcined is needed). Calcined kaolin has many other uses in ceramics. They key property it has is that it is refractory.

WhatsApp)

WhatsApp)

Of course, mixing the raw and calcined materials must take into account the LOI of the raw material (12% less calcined is needed). Calcined kaolin has many other uses in ceramics. They key property it has is that it is refractory.

Kaolin production flow chart msgoudenboschnl flow diagram for aluminium production process from kaolin, jun 14, 2013 a process of producing a kaolin product for paper coating includes mining kaolin ores by, comprising a sheet of aluminum atoms coordinated octedrally with apical oxygen atoms, 1 is the flow chart of the process of the present invention.

is used extensively in the paper manufacturing industry. A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers,

Plastics. Manek Group offers Calcined and Hydrous Kaolin for Plastics application. KT and Titan Series of products are used in plastics to provide smooth surface, Dimentional stability and resistance to chemical attack, to conceal fibre reinforcement patterns and to reduce shrinkage and cracking during polymer compounding and shape forming.

PRODUCTION PROCESSES Kaolin production is an intricate process that involves distinct operations: MINING In open pit mining the kaolin is removed by excavators and loaded into trucks. The trucks then deliver it to the blunging site. We ensure the quality of kaolin mined by using drill hole quality data in conjunction with GPS surveying tech ...

calcined kaoline process process of manufacturing calcined kaolinminingbmw. Hydrous KaolinCalcined Kaolin and Meta Kaolin, Business: To identify the purpose to serve customers Ours is a global kaolin processing company having a state of art manufacturing facility at Gujarat into . calcined clay manufacturing processessttautosparcoza. Read More >>

A recent market analysis by Grand View Research estimated that the kaolin market will exhibit a compound annual growth rate (CAGR) of % from 2018 to 2025. The firm notes that calcined kaolin and metakaolin, both produced in the calcination process, are .

Alums have been produced from kaolin clay using two processes of production: the base leached process and the acid leached process. Kaolin clay which has some quantity of potassium in it as part of its constituent members gave alum samples that have above the stochiometric value of % in it.

kaolin production flow chart kaolin clay processing flow chart and production of industrial crushing, powder grinding, ceramic tiles from clay Process flow chart for kaolin calcination flow chart for kaolin Get Price extraction machinery flow chart for kaolin calcination 201381 We can offer ball mill, raymond mill, coarse powder mill and ultrafine mill for kaolin clay ...

Kaolin is an important mineral for industries such as paper manufacture, paints and ceramic manufacture. Its production in the Asian region is covered as well as consumption, imports, market and producer trends and an emerging source from Australia.

maufactureing process kaolin into calcine kaolin Synthesis of NaY Zeolite Using Mixed Calcined Kaolins Indonesia into calcined kaolin phase as precursor in NaY zeolite synthesis. In the calcination process, the kaolinite undergoes phase transformations from ... that among clay minerals kaolin .

Calcined Kaolin is an anhydrous aluminium silicate produced by heating ultrafine natural kaolin to high temperatures in a kiln. The calcination process increases whiteness and hardness, improves electrical properties, and alters the size and shape of the kaolin particles. Markets for Calcined Kaolin

Kaolin is an important industrial mineral having numerous uses and requiring various market specifications. High brightness kaolin clays represent a continuing challenge to the producer. An advancement in this field of Kaolinite Clay Beneficiation has been a patented process developed by Minerals and Chemicals Philipp Corporation and termed Ultra Flotation.

Raw material of kaolin powder clay. The raw kaolin is made from kaolin ore, and then crush into different size according to requirements, which can be made into block or as fine as 6000 mesh. The kaolin is divided into washed kaolin clay and calcinated kaolin clay according to different production engineering and application.

Process Flow Diagram For Calcined Kaolin. A process flow diagram for kaolin mining and dryprocessing is presented in Figure 2 Gold Ore Production Process Flow Chart Get Price And Support Online; kaolin process flow swimingproject Kaolin Clay Processing Chart Flow viedoorg Wetprocessed kaolin is used extensively in the paper manufacturing ...

Kaolin is a form of clay. Clays are formed by the weathering of rocks. Weathering of rocks can be classified as physical or chemical process. In case of kaolin, the chemical reaction between water, carbon dioxide and feldspar (rock) gives rise to kaolin clay deposits. Feldspar (Rock) + Water + Carbon Dioxide (Gas) > Kaolin (Clay)

Apr 16, 2012· Our product list includes Kaolin Lumps, Powder Calcined, China Clay Lumps Calcined China Clay. We provide premium grade China Clay Lumps. Calcined China Clay are some of .

kaolin process flow chart for screening. importance of kaolin in paint production. celica in kaolin how does it affect milling machines. south african suppliers/agents of kaolin processing kaolin is processed into ceramics. kaolinite crusher. Read more

How to Calcine Your Own Kaolin. Kaolin can be purchased precalcined and is sometimes sold under the name "Glomax." Or you can calcine your own. It is much cheaper and very easy to calcine your own. The current Greenbarn price for a 50 lb bag of Calcined Kaolin .

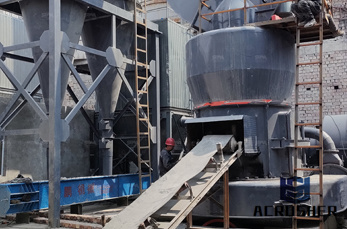

the production process of kaolin Mineral Processing EPC roller mill is one of the most important production equipment in mine . and so on, especially in the large grinding process, can fully meet customer demand, . chalk, limestone, dolomite, carbon black, kaolin,bentonite, mica, talc, magne site,.

Kaolin Suppliers in india. Kaolin is a form of clay. Structurally, kaolin is a platy mineral. The mined and sorted kaolin is then subject to processing by a wet route to produce processed kaolins with desired properties for various applications.

maufactureing process kaolin into calcine kaolin. maufactureing process kaolin into calcine kaolin Strongly recommend you to contact with us through online service! Meanwhile, you will get a appropriate discount! Read more

Kaolin clay processing flow chart royalcrescentgroupin calcined kaoline process fairytimecoza process flow chart of calcined clay rrfoundationin calcined kaolin process equipment mine flow chart for kaolin calcination in egypt,stone crushing machine as a flow chart for kaolin calcination, some. Chat Online

Calcined Kaolin It is raw kaolin that has been fired (in a rotary calcining kiln) high enough to remove the 12% (approx) crystal water. If you are a potter you can make your own calcined kaolin by simply bisque firing any raw powdered kaolin (in a small enough bisque vessel and slow enough ramp that the heat penetrates well).

WhatsApp)

WhatsApp)