gear cutting wizard on 4 axis mill YouTube

Jul 04, 2015· DIY yourself gear cutting on a 4 axis CNC mill using slitting saw and linuxcnc Now you can make just about any gear with any pressure angle you wish. free gear .

WhatsApp)

WhatsApp)

Jul 04, 2015· DIY yourself gear cutting on a 4 axis CNC mill using slitting saw and linuxcnc Now you can make just about any gear with any pressure angle you wish. free gear .

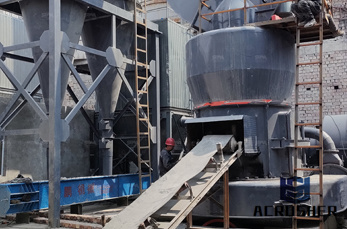

The Pfeiffer mill is designed to produce 35 tph of quicklime at a fineness of 10 % R 150 µm and will come equipped with a 200kW gearbox. MPS mills have been used successfully for a great many years in works of the chemical, gypsum and lime industry where limestone, quicklime or gypsum are ground.

First Generation Roller Mill Drives. Philadelphia Gear® was one of the most successful lines of dynamic pulverizer drives ever developed. Working with OEMs Babcock Wilcox, Combustion Engineering (CE) and Foster Wheeler, we supplied the gear drive for the MPS89, CE and MBF coal pulverizers, respectively.

Basically the vertical mill gearbox serves to transmit the motor couple to the grinding table. Moreover, it directs the grinding forces into the mill foundation. Unlike on conventional gearboxes, these two functions are completely separate on the MultiDrive ® what makes it so unique and trendsetting. Therefore, delicate gearbox components are ...

DFMEA of a Roller Mill Gear box . ... levels of effects of failure and corrective actions to be taken in the design phase for BevelPlanetary Vertical Roller Mill Gearbox.

Mar 05, 2014· installation of mill motor to gear box vertical mill Grinding ... Vertical Mill Gearbox China Gearbox,Gear Box. Vertical Mill Gearbox, safe and reliable in operation and convenient for ...

HYPERMESH and ANSYS, we model and optimise the Gear Box according to Mill and customer requirement. GEAR BOXES FOR BOWL MILLS PLANETARY GEAR BOX: Epicyclic or planetary gearbox is lighter, compact, efficient and stronger than other Gearboxes of same capacity. Being more efficient makes it to consume less power compared to other gear drives.

vertical mills. Lubrication, sealing The MPS mills built by Pfeiffer are lubricated by means of an oil sump or oil circulation system, in accordance with the operating conditions. Synthetic lubricants (ISO VG 680 or VG 1000) and a special sealing concept ensure the high operational reliability of the mills .

Feb 26, 2013· The WPV threestage bevel and planetary gear units, all of which are equipped with slide bearings, have reached an impressively compact design. This is made possible by torque split in the ...

In addition, we continually develop new technologies, upgrades, replacement parts, and inventory management programs to improve reliability and performance, and to reduce operating and maintenance costs of our BW Roll Wheel and E/EL pulverizers, as well as CEtype mills.

Ulf Weller, Senior Design Engineer, MAAG Gear AG Rocco Amato, Head of Mill Gear Engineering, MAAG Gear AG Drive trains of vertical roller mills are usually equipped with heavy duty gearboxes with a horizontal input shaft and a vertical output shaft. Increasing mill sizes bring the existing gearbox concepts to their limits, however.

Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production. Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW. In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill production.

Nov 22, 2012· MPS Mills Mill Parts – Welcome to The MPS Coal Pulverizer . There is no other vertical spindle coal pulverizer with more installed combined . efficiency in an MPS mill.

Gearbox for Mill This gear reducer is most suitable for driving a cement raw mill a clinker mill, a coal mill, and a slag mill, etc.. We are one of the world''s leading companies for a gear reducer of a mill and have supplied more than 500 sets to world''s customers which are highly evaluated.

are the OEM''s for most of the Bowl Mills of Chinese make, we can offer one to one replacement for all your needs of Vertical Mill gear boxes. Besides above, NGC also manufacture Gear Boxes for following applications:For Plate Rolling Mills For Bar Wire Rolling Mills For Wind MillsFor Rubber Plastic Machines For Railway Locomotives

Vertical Roller Mills. The criticality of the power generation industry means that gear system reliability is key. Designed in close cooperation with mill manufacturers, our vertical roller mill drive series demonstrates long bearing life, high power density and an optimised product lifecycle.

Engineering Division Services. Gearbox consulting Engineering consulting ... Vertical Boring. Vertical Boring up to diameter Fabrication welding capacities ... ID welding Other capacities. Milling table 8m long and up to 15 ton work piece Pressing up to long by 400 ton press Machinery assembly, fitting and testing facilities

Chongqing Gearbox is China vertical mill gearbox manufacturer. JLXJLP series vertical mill gearbox is for vertical mills of cement production lines and vertical mediumspeed mills of coal production lines. JLX series reducer adopts twostage driving. The vertical mill gearbox meets the standard JC/, approved by the Technical Committee for Standardization of Building Material Industry.

MVR vertical roller mill with conventional drive. With a planetary gearbox and up to six grinding rollers, the MVR mill is the optimum solution – also in terms of economy when it comes to producing small to medium output rates.

Vertical Mills. Vertical mills (such as bowl, roller grinding, ballandring, and roller mills) are mainly used for comminuting limestone, clinker, slag, lime, gypsum, and ores for the building industry, and coal in the coal preparation. They reduce raw material from .

With our crossfleet abilities, we can service your BW''s EL and MPS, BPEG''s ZGM and Foster Wheeler''s MBFtype mills and pulverizers as well as offer high quality and a full spectrum of solutions for each. We offer customized solutions for all boiler mills and coal pulverizer types, regardless of the original manufacturer.

offers 12,812 vertical gearbox products. About 32% of these are speed reducers, 27% are gearboxes, and 1% are construction machinery parts. A wide variety of vertical gearbox options are available to you, such as helical, cycloidal, and bevel / miter.

Feb 21, 2017· Liam Riggs explains the mechanics and the math required to cut a spur gear. ... Gear Cutting on a Horizontal Mill using a Dividing Head Duration: 35:33. Keith Rucker ...

Our skilled technicians have the power and expertise to handle everything from preventative maintenance to major coal pulverizer overhauls to keep your mills running smoothly and efficiently. We supply all basic tooling, labor and supervision to repair any part of the pulverizer from the gearbox to the raw coal feeder.

WhatsApp)

WhatsApp)