How Cyclone Separator Works YouTube

Jun 02, 2017· This video explains what a cyclone separator is, how it functions, its advantages over filters and its typical applications. The 3D model in the video can be found at or 3Dknowledge ...

WhatsApp)

WhatsApp)

Jun 02, 2017· This video explains what a cyclone separator is, how it functions, its advantages over filters and its typical applications. The 3D model in the video can be found at or 3Dknowledge ...

A cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. Rotational effects and gravity are used to separate mixtures of solids and fluids. The method can also be used to separate fine droplets ...

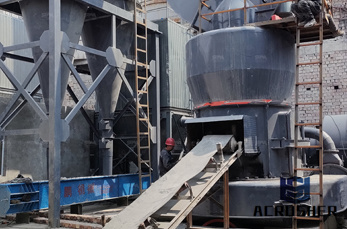

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

offers 2,045 separator for cement products. About 20% of these are mineral separator, 3% are separation equipment. A wide variety of separator for cement options are available to you, such as magnetic separator, gravity separator, and sprial separator.

cement mill dynamic separator YouTube 4 Sep 2013 ... Cement mill and dynamic separator Europe production (28 May 2012) Gulin supply Mining and construction equipment for mineral handling. for the cement industry FTP Directory Listing Total cement production in the European Union amounted to 172 .... Releases from the ...

VSeparators KHD International KHD Humboldt Wedag ... to the cement over 155 years of experience in the cement industry, KHD is a global leader in cement .

"best available techniques" for the cement industry – FTP Directory .. CEMBUREAU – the European Cement Association, based in Brussels, is the representative organisation for the cement ... for draft ... second combustion device between the rotary kiln and the preheater section. In the ... dynamic air ("highefficiency") separators offer the most flexible ...

Dynamic separator is a device that separates course and fine materials as reject and product. It can be used in many areas of industry such as cemet, energy, mine, metals and agriculture. Dynamic separator consists of some main parts such as blades (rotor, static, vortex), casing and reject box.

Dynamic separator is designed for separation of largesized fractions from small ones. A distinguishing feature of the dynamic separator is ability to regulate the grinding fineness by means of rotor rotation frequency and stator blades setting angle.

cement mill dynamic separator animation. Products List. Cyclonic separation . Cyclonic separation is a method of removing particulates from an air, gas or ... oils and gases, and in the cement industry as components of kiln preheaters. More details » Get Price.

static and dynamic seperator in cement mill. Highefficient cement manufacturing with POLYCOM and SEPOL, static and dynamic seperator in cement mill,For cement grinding, the highpressure grinding roll (HPGR) POLYCOM and the staticdynamic separator SEPOL PC can be installed as a finishgrinding circuit or, in combination with a ball mill ...

and separator technologies, the cement quality and product portfolio, the environmental standards, the state of the plant and the plant operation itself. Efficient and correctly ... turbine (dynamic classifier), which at first was a small axial turbine (1st generation) and by the end of this development had become a radial turbine (3rd genera

The CDS hydrodynamic separator uses swirl concentration and continuous deflective separation to screen, separate and trap trash, debris, sediment, and hydrocarbons from stormwater runoff. CDS captures and retains of floatables and neutrally buoyant debris mm or larger, effectively removes sediment, and incorporates a nonblocking screen.

dynamic separator for cement . khd dynamic separator for raw mill Grinding Mill China. khd humbolt cement mill separator. SKSLseparator and ball mill for crushing, drying and grinding raw . in semifinish mode in front of two ball mill systems with ... Contact Supplier

An overview of cement manufacture 2. Cement grinding and the different mill systems ... introduced the 1st air separator in 1939 for closed circuit grinding; o Years of development led to a highly ... CPB single dynamic separator system reduces investment cost, plant .

air separator for cement mill YouTube. May 23, 2018· Cement mill dynamic air separator videoCement Machinery Cement Plant Machinery, Cement Machinery The flow sheet shows the ball mill in close circuit with air separator The feed is given at one .

AbstractShree Cement / Suratgarh are operating a semifinish grinding system type "S" which consists of a roller press below the VSeparator. The Static Separator is directly connected to the air inlet spiral of the SKS Separator. The ball mill discharge is feed to the top of the SKSSeparator.

Nov 07, 2009· dynamic separator. Can any body suggest reference books for designing separator for raw and cement mill,Or please suggest consultant for dyamic separator design. Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply.

mostly performed in closed circuits: The ball cement mill (CM) is fed with raw materials. The milled product is fed via a recycle elevator to a dynamic separator. The high fineness stream of the separator constitutes the final circuit product, while the coarse material returns back to the CM to be ground again.

Separators in the cement industry ... Dynamic separators are classified in three categories (*), the first, second and third generation. In first generation separators, the air flow is generated by a fan within the body of the classifier. In second generation, the air flow .

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS 06 The different manufacturers of vertical mills mainly distinguish themselves in the shape of the grinding rollers and therefore the grinding plate''s profile. The dynamic separators are the same as the ones used on tubular ball mills, obviously adapted to the vertical grinding machinery.

Feb 06, 2014· Dynamic technology: Solutions through trustworthy innovations. The classifier can separate particle sizes of up to 1 μm (and generate products with residues of 1% R .

These separators has been developed in the beginning of the eighties (O''Sepa from Onoda Cement). As the second generation, the air flow required for the separation is produced by an external fan. The separator material feed is carried out mechanically by means of suitable continuous conveyors.

High Quality Separators For Any Type Size Of Cement Plants. A well efficient separator will always prevent the particles from over grinding which on the other hand leads to wastage of energy. The separators can be classified into two types: the dynamic separators and the static separators.

WhatsApp)

WhatsApp)