Steel mill cobble YouTube

Jun 01, 2011· Rolling mill mishap. پاک سٹیل مل .اسلام آباد .PAK STEEL MILL ISLAMABAD PAKISTAN 2013 VISIT Duration: 2:44. jan iuy 51,624 views

WhatsApp)

WhatsApp)

Jun 01, 2011· Rolling mill mishap. پاک سٹیل مل .اسلام آباد .PAK STEEL MILL ISLAMABAD PAKISTAN 2013 VISIT Duration: 2:44. jan iuy 51,624 views

HPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining. The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent years. After these developments, an HPGR based circuit configuration would often be the base case for certain ore types, such as very hard, abrasive ores.

You are guaranteed to benefit from SMS groups longstanding technological expertise in hot rolling processes for the aluminum industry. Out of this comes highly developed technology, automation and service packages that feature customdesigned solutions for all your wants and needs.

roll mill crusher limestone alibaba. The company has a complete testing capacity and a highlyefficient and complete product quality inspection tracking system. machine is equipped with sealing cap for rollers which can control the harmful dust spread to create a better production environment. which supply of roll mill crusher limestone respectively.

The following table clearly illustrates why Steel Head Rod Mills have greater capacity than other mills. This is due to the fact that the diameters are measured inside the liners, while other mills measure their diameter inside the shell. ... The rods roll through the cascade zone until they come to the "toe" of the load. At this point the ...

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM D to LM D), with table diameters from 1,200 to 2,000 mm. Larger mills with two, three and four rollers and modular structures (LM D to LM D), with table diameters from 2,100 to 4,300 mm.

1254 Double Roller Mill Video 1254 Triple with HDFY 3Point Scraper. 1254 Roller Mill with 18'' Belt Discharge Flyer Click to request More Info . Built with the operator in mind, our Roller Mills are easy to adjust, easy to operate and easy to maintain. Capacities: 700 to over 4500 bushels per hour among the highest capacity on the market

May 21, 2018· aplikasi ini digunakan untuk menentukan total maksimal berat kompon yang akan di roll mill. Jika total berat kompon lebih dari kapasitas roll mill, maka dispersi ban saat compounding akan jelek. Semoga bermanfaat.

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

Used Farrel two roll mill, 60" wide x 22" diameter rolls, cored rolls, unitized base, 150 HP 480 Volt AC 450 RPM motor, :1 ratio Hansen gearbox rated to 222 HP max with a service factor, hp hydraulic unit, Farrel serial# 79A1171.

Two Roll Mill Capacity Chart Denmark moulindemembrebe. two roll mill capacity chart fortunemediagroupin Theflowchart of computer aided design for the pass design of Y shape threeroll mill sys, capacity of 30000t alloy steel bar mill,it was considered that the threeroll mill was the lim.

Hani is the leader of steel rolling mill equipment from China with decades experience engineers, we provide a wide range of rolling mill including bar wire rod rolling mill, continuous section rolling mill and electric arc furnace.

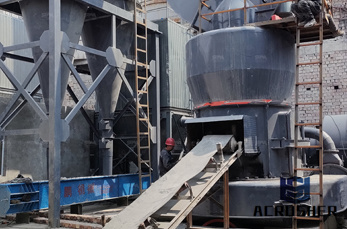

High Capacity Roller Mill Product introduction: Brief Introduction of Roll Mill: Roll mill is designed by our RD department on the basis of multiple innovation and testing. It has been proved by thousands of customers that our machine has outstanding features, stable quality, easy operat

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

For many years I have accepted and used the method proposed by E. Stalinsky (ref. 1) for the determination of open roll mills load. This method establishes a value of 19 liters per square meter of the front roll surface, based on considerations that are, in my opinion, subjective and questionable.

Tandem coldmill solutions from Primetals Technologies stand for high product yields combined with flexible production, low operational costs and simplified maintenance work. Depending on the product mix, the production capacity of continuous tandem mills from Primetals Technologies can exceed million tons per year.

Our increased roll configurations in lowprofile electric roller mills allow for additional adjustment with the use of a single lever. Automatic''s lowprofile electric rollers are available in 4,, 8, and 10 roll configurations with our LPE 700, LPM 200, and LPE 500 models.

We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match. Plastics and Composites. Plastics and Composites. ROSS mixers, blenders and dispersers are used throughout the plastics and composites manufacturing industries. ... Three Roll Mills, and MultiShaft Mixers are widely ...

The Flat Roll Group is comprised of two of SDI''s six electric arc furnace steel mills – one at Butler, Indiana and one at Columbus, Mississippi ― which have a combined annual production capacity of million tons of hot roll steel sheet as well as eight downstream coating facilities.

Model 7312KVH Three Roll Mills. The 7312KVH mill is designed to make operation easier, increase production and product quality, and to provide a safe, efficient production mill with the features most often requested by customers.

a better grind starts with a better mill. home. rms roller grinder

roll bite and in a typical Cold Tandem Mill, work roll temperatures normally fall in the range of 55oC – 70oC with strip recoil temperatures and interstand strip temperature rarely exceeding 160 oC depending on product. Roll Bite temperatures in slower heavily drafted stands can peak in the region of 300oC, diminishing with the

Tworoll mills. Strongly designed TwoRoll Mills of any size and for any application are ready to our customer´s disposal. Many years experience on this field is transferred on very powerful equipment. Having a full control on manufacturing process on the mill rolls give us a large advantage.

Apr 27, 2015· Each 26″x84″ tworoll mill, requires around 180 kW (minimum) motor power – totaling to 360 kW (=180 x 2) only for the mills. For a similar capacity mixer, a TSS downstream will not seek more than 300 kW power (again, there is energyefficient models available here). So, this rough calculation, when a TSS replaces the traditional dumpmill ...

WhatsApp)

WhatsApp)